Our Extra

Virgen Olive Oil (EVOO)

Tasting notes

Oil with a delicate scent; there´s presence of olive leaf, freshly cut grass and green almond on the nose. On the palate, there is a slight and short bitterness, which gives way to a medium and persistent spiciness, both attributes very balanced. The fruitiness is green, fresh, with fig and chicory. Harmonious, balanced oil with a great finish.

How we produced and obtained the quality of our oil.

Have the total control of the whole process, give us the security of the quality we offer.

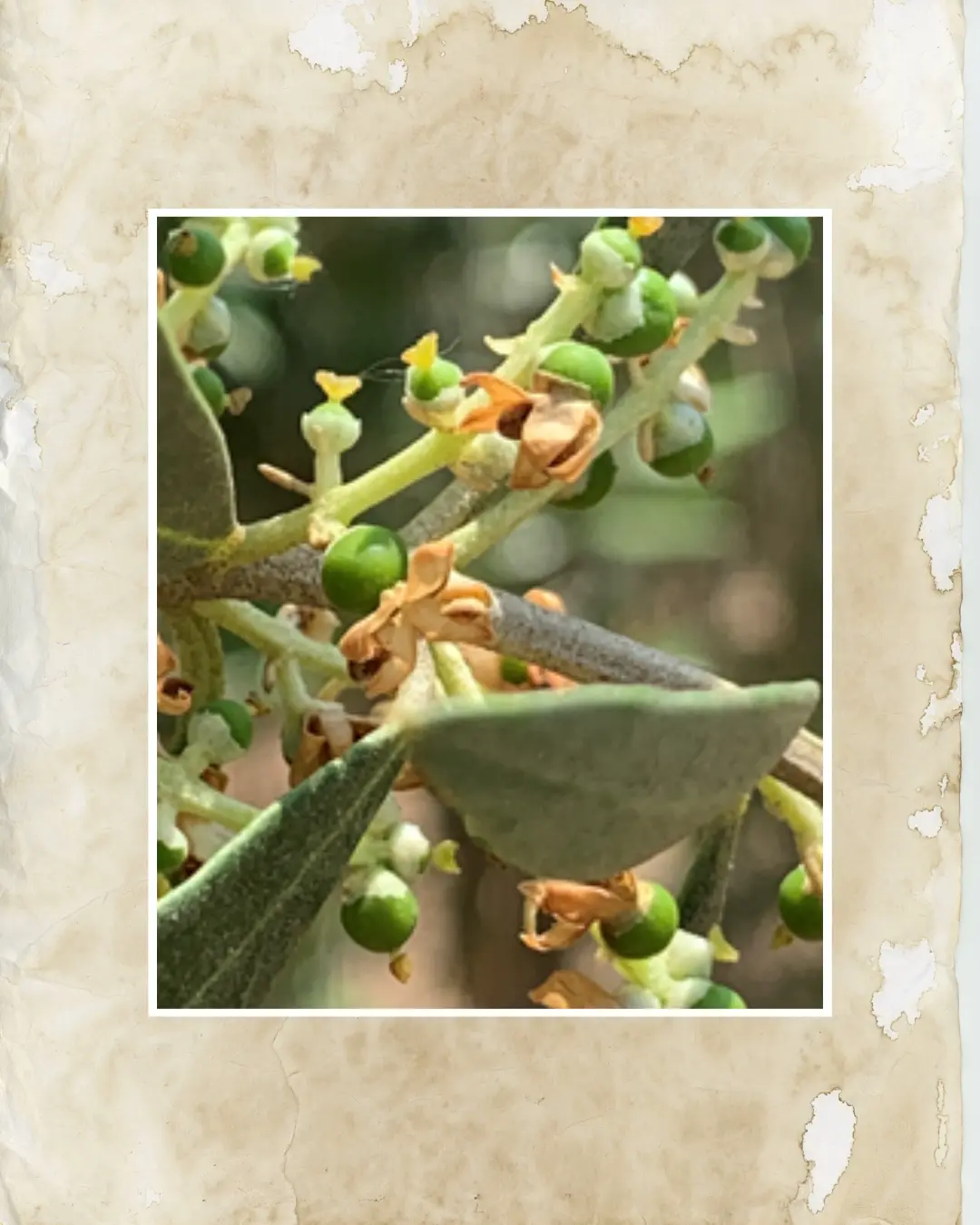

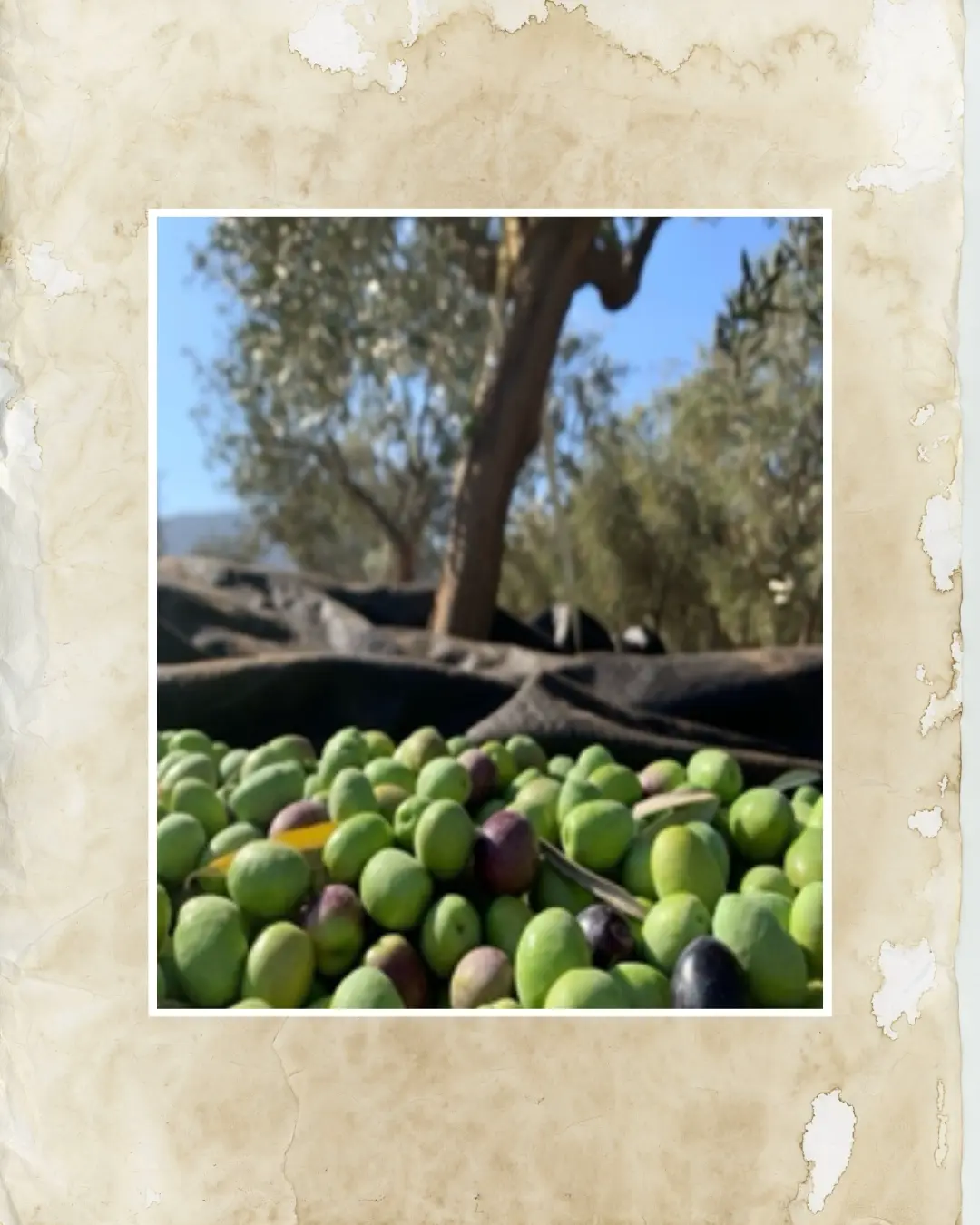

The production of our oil begins in our orchard, taking the necessary agricultural care for a good growth of the olive trees. Once they are blooming, we begin to pay attention to the fruits and its water and nutritional requirements, until the right moment of ripening to start the harvest, which takes place between the months of April and July.

We process our olives within 24 hours of harvesting to reduce the time of the natural oxidative process of the fruit. The extraction of our oil take place in our own mill, controlling the temperature and humidity of the paste.

Storage is carried out in our air-conditioned cellar, in large stainless-steel tanks, awaiting for its bottling and subsequent dispatch to our customers.

Reception and processing

In our mill, the harvested olives are stripped, washed, and milled, passing through two toothed discs. The resulting paste is kneaded in large containers with steel blades so that the oil content begins to be released. Subsequently, the oil is centrifuged and separated from the orujo (solid waste and water).

As part of our commitment to the environment, the residues from the entire production process is handled and composted for months before being used as natural fertilizer in our orchard. This makes the production of our oil a circular, sustainable and waste-free process.

Decanting and water dismiss.

After the oil is obtained at the mill, it is decanted in conical bottom tanks to eliminate the suspended material and the remaining water molecules. After decanting, our oil is stored in large stainless still tanks, awaiting it’s bottling and further shipment to our customers.

EVOO Line process

We do not quit to our olive oil quality!

Accomplishing with all the standards of a virgin extra stipulated for the IOC (International Olive Oil Council).

- Healthy and high-quality olives.

- Low temperature process.

- Acidity under a 0,2%.

- With no organoleptic defects.

- Fruity taste with mediums bitterness and spicy.

- We controlled each step of the process

- Pesticides and herbicides free.

- 100% pure olive oil.

We do not quit to our olive oil quality!

Accomplishing with all the standards of a virgin extra stipulated for the IOC (International Olive Oil Council).

- Healthy and high-quality olives.

- Low temperature process.

- Acidity under a 0,2%.

- With no organoleptic defects.

- Fruity taste with mediums bitterness and spicy.

- We controlled each step of the process

- Pesticides and herbicides free.

- 100% pure olive oil.